Stainless steel is a popular material used in a variety of products and applications. It is known for its durability and resistance to corrosion, making it a great choice for a variety of uses. However, stainless steel is not invincible and can be damaged in certain circumstances. Knowing what can damage stainless steel and how to prevent it can help ensure your products and applications are protected. Common causes of damage to stainless steel include exposure to high temperatures, prolonged exposure to moisture, and harsh chemical cleaners. Corrosion can also cause damage to stainless steel if the surface is not properly maintained. Taking the necessary precautions to prevent damage can help you ensure your stainless steel remains in great condition for years to come.

Definition of Stainless Steel

Stainless steel is a type of metal alloy composed of iron, chromium, and other elements such as nickel, molybdenum, and manganese. It has a range of qualities that make it an ideal material for a variety of applications. Its high corrosion resistance, strength, and durability make it ideal for use in kitchenware, medical equipment, appliances, and other items that need to be sanitary and resistant to wear and tear. Additionally, stainless steel is an economical material, making it a cost-effective choice for many projects.

Reasons Why Stainless Steel Can Become Damaged

When it comes to durability, stainless steel is a top choice in construction and home goods. Despite its ability to resist corrosion and damage, stainless steel can still sustain damage over time. The most common causes of damage include physical impacts, incorrect cleaning, and chemical exposure. Physical impacts can occur due to mishandling or collisions with other objects. Incorrect cleaning can lead to scratches and the buildup of dirt and debris which can weaken the steel. Lastly, chemical exposure can cause damage due to the reactive nature of certain chemicals in the steel. With proper care and maintenance, stainless steel can remain in great condition for years to come.

Common Signs of Damage to Stainless Steel

Stainless steel is a durable material widely used in industries ranging from construction to food production, but it is not indestructible. Like any material, stainless steel can become damaged, and there are common signs that indicate it needs to be replaced or repaired. These include discoloration, rust, pitting, flaking, scratching, and warping. All of these signs can lead to corrosion, which can lead to further damage and affect the performance of the material. Regular maintenance and inspection of stainless steel products is essential to prevent such damage from occurring. By being aware of the common signs of damage to stainless steel, you can take the necessary steps to ensure your equipment is functioning properly.

Preventive Measures to Avoid Damaging Stainless Steel

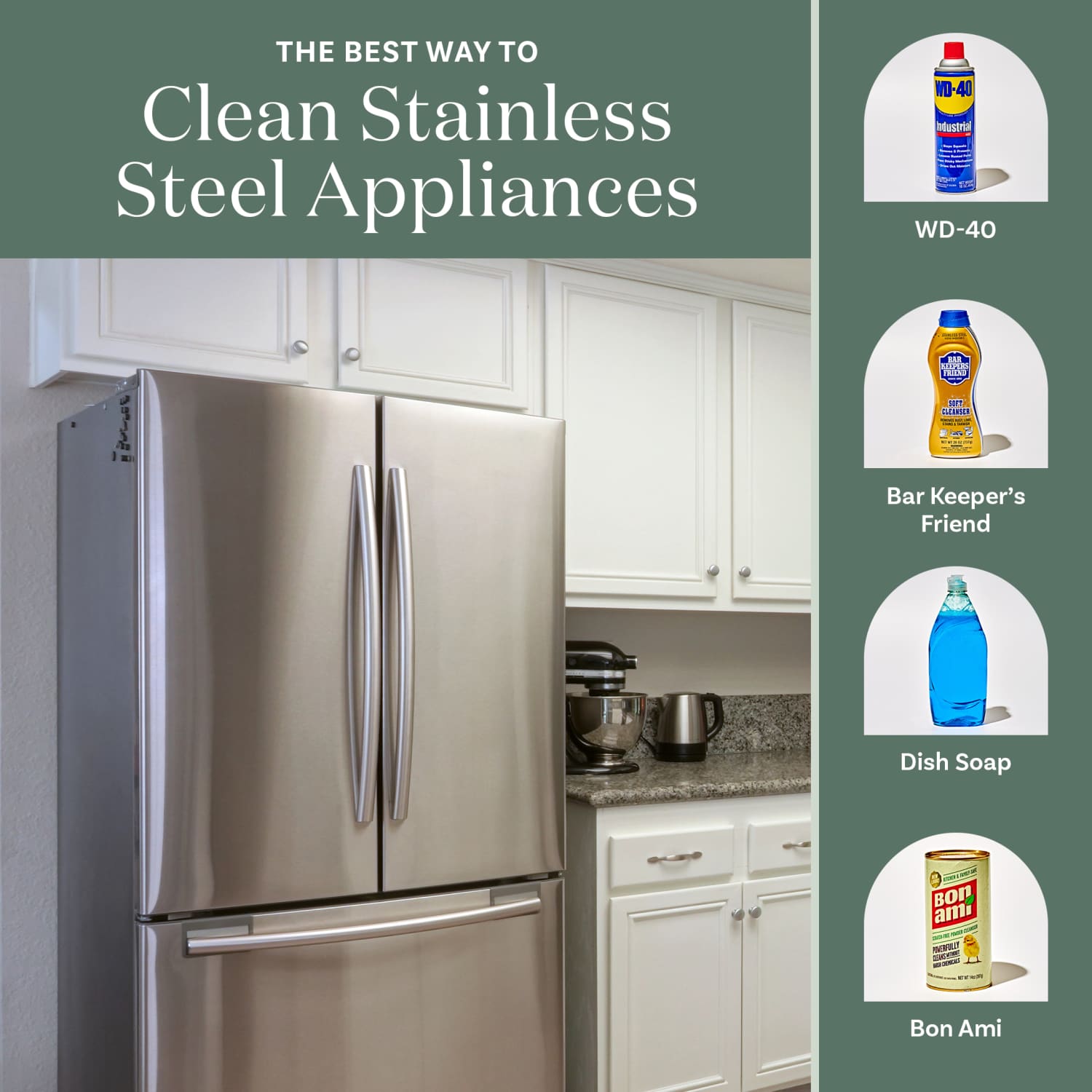

Stainless steel is an enduring and versatile material used in a variety of applications. Unfortunately, it’s also prone to damage if the correct preventive measures are not taken. To avoid damaging your stainless steel, cleaning should be done regularly with warm water and mild soap. Avoid using harsh chemicals or cleaners that contain chlorine as this can cause corrosion. Additionally, it’s important to dry the stainless steel promptly after cleaning to prevent water spots. It’s also important to protect the stainless steel from scratches, dents, and other forms of damage. To do this, use soft cloths, rubber mats, and non-abrasive pads for cleaning, and avoid using steel wool or steel brushes. Finally, store your stainless steel in a dry, low-humidity environment to prevent rusting and oxidation. Taking these preventive measures will ensure your stainless steel looks great for years to come.

Repair and Maintenance of Damaged Stainless Steel

Stainless steel is a durable material that can withstand years of extreme wear and tear. However, sometimes even stainless steel can succumb to damage. Proper repair and maintenance of damaged stainless steel is essential for preserving its integrity and aesthetic appeal. The first step is to identify the source of the damage. This can be done by inspecting the steel for any visible signs of corrosion or wear and tear. Once the source of the damage is identified, the appropriate repair method should be determined. Depending on the severity of the damage, this may involve cleaning, polishing, sanding, and repainting the steel. For more serious damage, welding or other metalworking techniques may need to be used. It is important to use the correct tools and materials for the job to ensure a successful repair. Proper maintenance can help keep stainless steel looking its best for years to come while ensuring its structural integrity.

Stainless Steel Finishing and Protection Methods

Stainless steel is one of the most popular and durable materials used in a variety of industrial and commercial applications. However, to ensure its longevity and to maintain its aesthetic appeal, it is important to understand the various finishing and protection methods available when working with stainless steel. Finishing techniques such as passivation, electropolishing, and mechanical polishing can help to remove impurities, while protective coatings like anodization and plating can help to extend the life of stainless steel parts and components. By understanding the different types of finishing and protection methods available, you can ensure the best possible results when working with stainless steel.

Environmental Factors that Affect Stainless Steel

Stainless steel is an incredibly versatile material, used in a wide range of products due to its strength, durability, and corrosion resistance. However, stainless steel is not impervious to environmental factors. Depending on the environment it is exposed to, stainless steel can be subject to oxidation, pitting, and discoloration. It is therefore important to understand the environmental factors that can impact the performance and aesthetics of stainless steel products in order to extend their lifespan and maintain a high-quality appearance. Factors such as temperature, humidity, and external pollutants can all have an effect on stainless steel and should be taken into consideration when selecting the right grade of stainless steel for a particular application.

Cost of Replacing Damaged Stainless Steel

The cost of replacing damaged stainless steel can vary widely depending on the extent of the damage, the size of the piece being replaced, and the type of stainless steel being used. It is important to understand the cost of replacing damaged stainless steel before investing in it for projects. The cost of stainless steel can vary from a few dollars to hundreds of dollars depending on the grade and size of the steel being replaced. It is important to take into account the cost of labor and other materials needed for the repair. Additionally, the cost of stainless steel can be influenced by the current market price for stainless steel. Understanding the cost of stainless steel is important for any project that involves stainless steel. Knowing the cost of replacing damaged stainless steel will help ensure that the project is completed within budget.

Conclusion

Stainless steel is a strong and durable material, but it is not impervious to damage. It can be damaged by exposure to certain chemicals or substances, extreme temperatures, abrasive cleaning tools, and improper storage conditions. It is important to be aware of these potential sources of damage in order to take steps to protect your stainless steel items.